A heating method that uses both hot air and far infrared rays

Introducing a hybrid heating method that combines hot air and far infrared rays

The heating method used in all of Antom Inc.’s (hereinafter referred to as “our company”) reflow and heating furnace lineups is a hybrid heating method that combines hot air and far infrared rays.

Also, by reducing the air volume (strength of the hot air) compared to standard hot air reflow methods, we are able to prevent the adverse effects of strong hot air, which is a beneficial heating method.

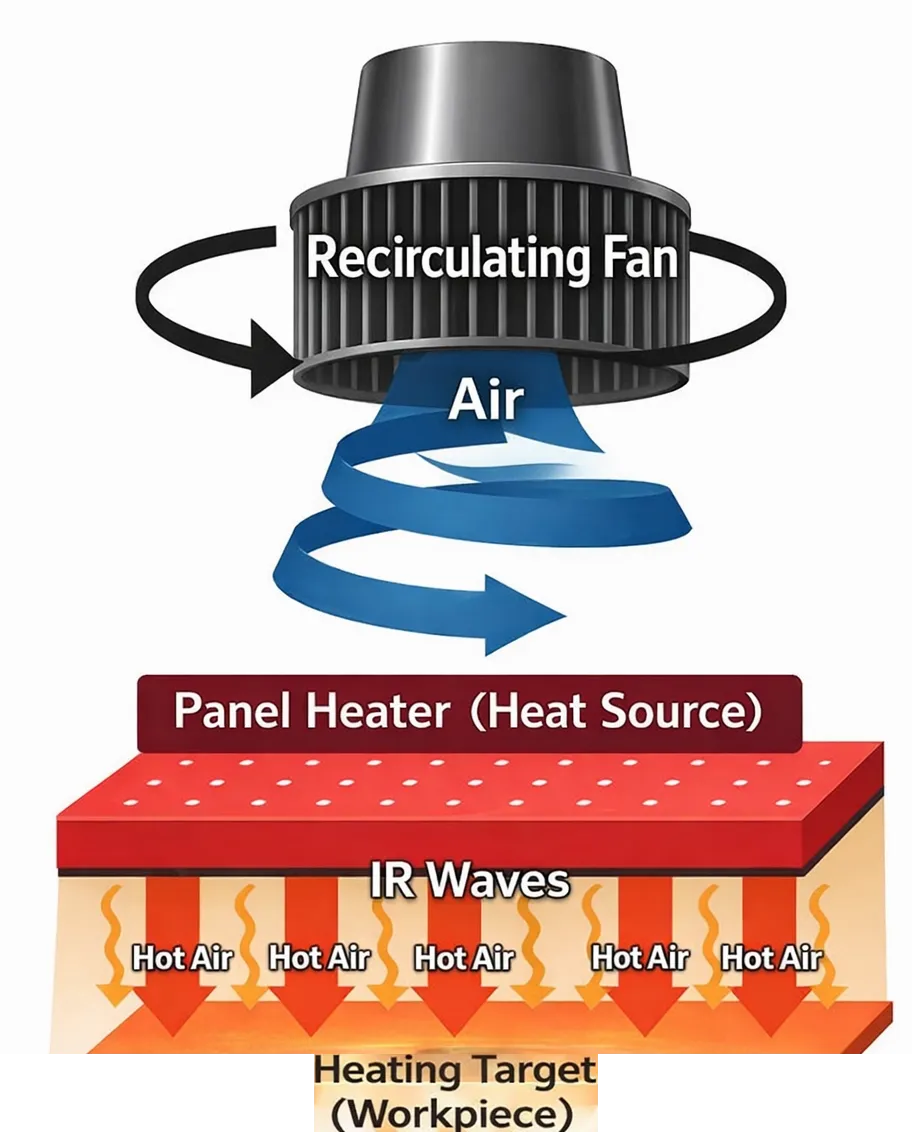

Below is a diagram that illustrates our unique hybrid heating method, which combines hot air and far infrared rays.

The air generated by the Sirocco fan passes through the panel heater, which is the heat source, and the heated air turns into hot air which heats the workpiece (target object).

Furthermore, by attaching a specially coated plate to the surface of the panel heater, the far-infrared effect is greatly improved, so that heating capacity is not reduced even when the amount of hot air is reduced. This is our company’s hybrid heating method which combines hot air and far-infrared rays.

Furthermore, when increased heating capacity is required, such as for workpieces with a large heat capacity, the hot air volume can be increased by adjusting the air flow, so it is not necessarily the case that heating is limited to a reduced hot air volume.

By utilizing this hybrid heating method that combines hot air and far infrared rays, the following benefits can be obtained.

The benefits of a hybrid heating method that combines hot air and far infrared rays

The greatest feature of our hybrid heating method, which combines hot air and far infrared rays, is that it reduces the amount of hot air, thereby minimizing the negative effects of strong hot air.

Below are some of the benefits you can gain by using our hybrid heating method, which combines hot air and far infrared rays.

| Improved soldering quality by suppressing flux degradation | Flux (an additive that increases the ability to remove the oxide film on the surface of the solder and the surface to be soldered), which plays the most important role in soldering, will deteriorate due to the hot air if the preheating time is long.As a result, the necessary flux becomes insufficient due to deterioration, and the solder does not fully activate during the main heating process, which can lead to defects such as insufficient wetting and spreading (self-alignment). Also, insufficient flux can cause air bubbles to not completely escape when the solder melts, and these can harden, causing voids. The simplest way to solve these problems is to reduce the amount of hot air and prevent the flux from deteriorating. |

|---|---|

| Ideal for drying solvents, fine parts, and thin workpieces | When drying solvents such as desiccant, applying strong hot air to the solvent can cause it to ripple or scatter. Similarly, thin workpieces such as fine components and film/flexible circuit boards can also be blown away or fluttered by strong hot air. To mitigate the effects of such strong hot air, our hybrid heating method, which combines hot air and far infrared rays with reduced hot air volume, is ideal. |

| Minimizes thermal interference with adjacent zones and zones above and below | If the hot airflow is strong, interference will occur with adjacent zones or zones above and below, and the temperature will tend to be pulled toward the zone with the higher set temperature.Therefore, it is not possible to create a large temperature difference between adjacent zones or above and below. However, our hybrid heating method, which combines hot air and far infrared rays, can minimize the temperature interference between adjacent zones or between the zones above and below by reducing the amount of hot air, making it possible to create a clear temperature difference. In addition, it is possible to minimize the space between adjacent zones, which also has the effect of suppressing temperature drops between zones. |

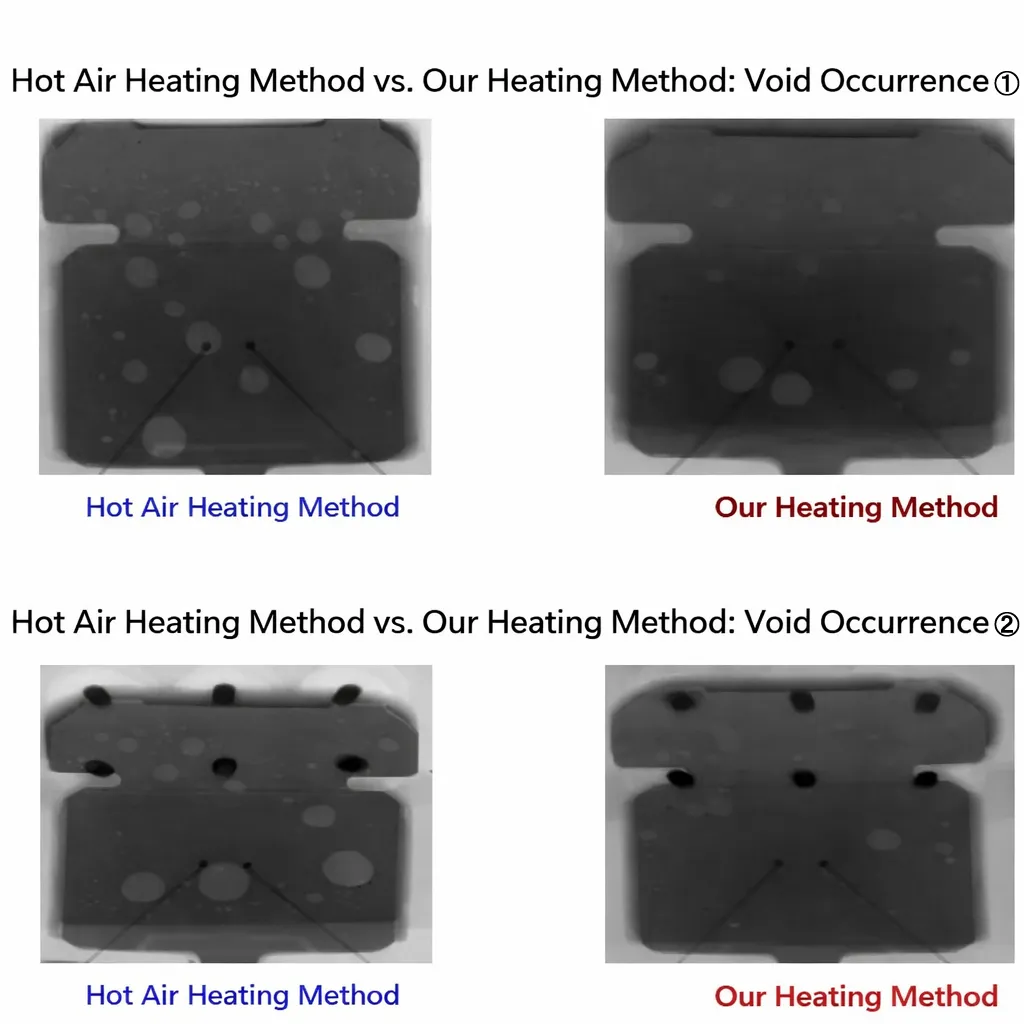

Below are photos comparing the occurrence of voids using a general hot air heating reflow (air reflow) method and our hybrid heating method, which uses a combination of hot air and far infrared rays.

Deterioration of the flux due to hot air inhibits the fluidity of the solder, and the gas that is generated as a result becomes trapped within the fillet (the solder shape formed between the lead and land), causing voids.

In other words, by reducing the amount of hot air, the flux does not deteriorate, and the number of voids can be reduced by maximizing the fluidity of the solder.

Although it is not possible to completely eliminate voids like with a vacuum furnace, this much void reduction can be achieved just by changing the heating method.

If you would like to reduce the occurrence of voids even a little, please consider our hybrid heating method, which combines hot air and far infrared rays.

Check out our hybrid heating method, which combines hot air and far-infrared rays, in action.

As mentioned above, all of our reflow and heating furnaces use a hybrid heating method that combines hot air and far-infrared rays.

Therefore, you can try out this hybrid heating method using the demo machine permanently installed in our demo room.

If you have any problems with your current heating needs, please feel free to contact us using the form below.

If you are in a hurry, please contact us by phone.

TEL: +81-45-476-3461 (Please ask for a sales representative)

Hours: Weekdays 8:30 AM – 5:30 PM

Product Inquiry Form

For inquiries regarding ANTOM’s reflow ovens for SMT applications, please contact us using the form below.

We welcome consultations not only for equipment selection, but also for demonstrations using actual machines and temperature profile measurements.