The Optimal Compact Reflow Oven Solution

The UNI Series, Designed for Installation Efficiency, Repeatability, and Energy Savings

The UNI Series: Compact reflow ovens used across industries and applications

A “compact reflow oven” does not simply mean a smaller machine. It means achieving the same level of repeatability and stability as mass-production equipment, even within limited installation space.

The UNI series is a conveyor-type compact reflow oven that concentrates only the performance truly required—from development, prototyping, and evaluation to pre-production processes, as well as semiconductor and electronic component applications.

The UNI Series: The definitive compact reflow oven solution

The UNI series is designed to satisfy, at a high level, the three essential requirements of a compact reflow oven:

1.Installation footprint

2.Temperature profile repeatability

3.Running costs (power consumption and nitrogen usage)

Based on application requirements, workpiece size, and the level of repeatability needed, users can select the optimal UNI model for their specific process.

Outstanding advantages as a compact reflow oven

Although compact in size, the UNI series uses a conveyor-type design. Unlike batch ovens, every workpiece is heated under identical conditions.

As a result, the UNI series eliminates common issues associated with batch ovens, such as operator-dependent variation, uneven stacking, and poor condition repeatability.

Especially in prototyping, evaluation, and reliability testing, the ability to reproduce results consistently is considered the highest value. For these applications, the UNI series is chosen by many customers.

Another key advantage is the option of not using large reflow ovens.

Large reflow ovens are optimized for mass production, but many manufacturing sites face challenges such as large installation space requirements, high setup costs, and excessive performance for low-volume or prototyping applications.

The UNI series is a compact reflow oven designed specifically to optimize areas where large reflow ovens are not the best fit.

In addition, UNI employs a proprietary heating method that combines gentle airflow with far-infrared heating. This approach addresses issues commonly encountered with large reflow ovens that rely on strong airflow.

For example:

– Workpieces such as thin substrates and fine components remain stable and do not move

– Gentle heating that is suitable for bumps and fine-pitch components

– Uniform heating that reaches not only the surface but also the interior

With these heating characteristics, the UNI series continues to be selected for semiconductor, electronic component, and fine-pitch assembly applications.

Three key features of the UNI compact reflow oven series

The UNI series is a conveyor-type compact reflow oven that supports nitrogen (N₂) operation and is characterized by its compact size, high-temperature capability, and energy efficiency.

In addition to production use for PCB assembly (soldering), the UNI series has a strong track record in heating applications across the semiconductor and electronic component industries, including screening, prototyping, drying, curing, aging, burn-in, thermal testing, inspection, and quality assurance processes.

The UNI series is designed to support Class 10,000 cleanroom environments as standard, with proven customization options achieving Class 100 cleanliness. As a result, approximately 70% of installed units are used in cleanroom environments.

In cleanroom environments, reducing installation footprint directly contributes to lower floor space costs. By adopting the UNI series, customers can improve area productivity while maintaining stable and repeatable thermal processing.

| Small size | Our mainstay is small heating furnaces, and we have established an unrivaled market share in transportable heating furnaces of 2m or less, which are widely used in various fields such as packaging, electronic components, semiconductors, and research and development. I’m here. |

|---|---|

| High temperature | Since it is possible to set high temperatures of 350℃ or higher, we have a lot of experience with severe heating conditions such as high melting point gold-tin solder joints and workpieces and jigs with large heat capacity. |

| Energy saving | Nowadays, carbon neutrality is attracting attention, and energy saving is one of the important points when selecting equipment. Our heating furnace has a structure that takes advantage of its compact size, resulting in significant reductions in electricity consumption and N2 consumption. |

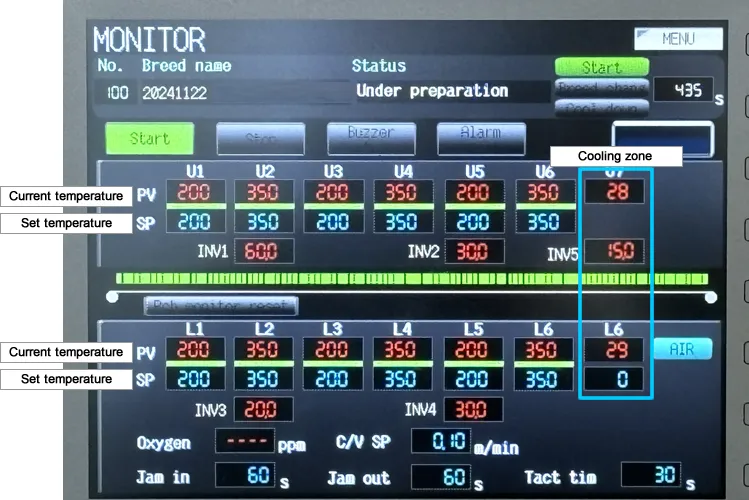

No attraction to adjacent zones even with a temperature difference of 150°C or more

With a typical large hot stove, when the temperature difference becomes large, the temperature is attracted to the adjacent zone with a lower temperature. However, with our N2 flow furnace, there is no temperature attraction to adjacent zones even with a temperature difference of 150°C or more.

Because the temperature difference between each zone can be set to a large value, a wide variety of profile arrangements are possible even with a small size. (Since there is no need to set the temperature in units of tens of degrees as with large hot stoves, it is possible to meet temperature profile conditions even with a small number of zones.)

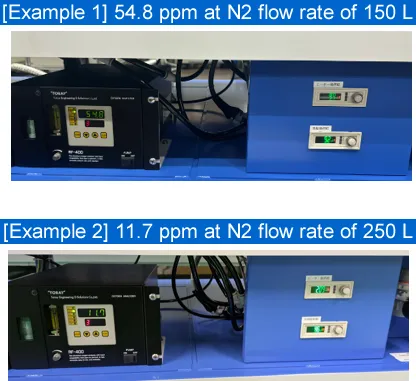

Achieves 50 ppm or less at N2 flow rate of 200 L/min

Our unique combination of far infrared and hot air heating and a highly airtight structure reduces the amount of N2 used and achieves low oxygen concentrations (50ppm or less).

For reference, it can be used at a furnace oxygen concentration of 100 ppm or less, and of course it can be used at an actual value of 50 ppm or less, and is often used in industries that require low oxygen concentrations such as semiconductors.

Taking advantage of this low oxygen concentration, it has a long track record as an N2 reflow soldering process for semiconductor devices, including chip mounting in the semiconductor post-processing, burn-in testing of lead frames, and solder ball mounting of connectors.

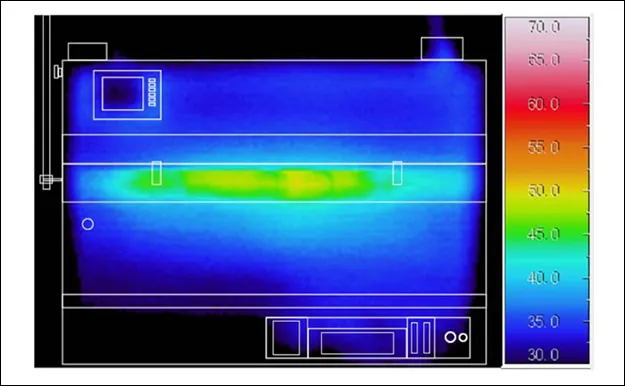

Achieving energy savings by strengthening the insulation structure

Some of our reflow ovens and heating furnaces can be set up to a maximum of 350℃, and the upper limit of the temperature setting tends to be higher than that of general reflow ovens and heating furnaces.

Therefore, in order to prevent the equipment’s outer panel temperature from rising too high, we strengthened the insulation structure so that the outer panel temperature remains below 50℃ even when all zones are set to 350℃.

The above thermograph data was measured with the UNI-6116S, the model with the highest temperature setting (350℃) in our lineup, when all zones were set to 350℃.

Even when all zones are set to 350°C, the outer panel temperature can be kept below 50°C, allowing equipment to be used without putting a burden on workers or the air-conditioned environment in the factory.

Energy efficiency through significant reduction of nitrogen consumption

To achieve an in-oven oxygen concentration of 200 ppm, the UNI series can reduce the required nitrogen flow rate to 150 L/min or less.

Because continuous nitrogen consumption has a direct impact on monthly running costs, reducing nitrogen flow contributes not only to energy savings and environmental considerations, but also significantly to cost reduction at the factory level.

Especially at high temperature settings, oxidation becomes more pronounced, making it necessary to lower the oxygen concentration accordingly. This typically requires an increase in nitrogen consumption.

As a reference, the UNI series can operate at in-oven oxygen concentrations below 100 ppm, and proven results show operation below 50 ppm as well. This performance has led to widespread adoption in industries requiring strict low-oxygen environments, such as semiconductors, electronic components, automotive, and medical applications.

Why the UNI series continues to be chosen as a compact reflow oven

The primary reason the UNI series continues to be selected as a compact reflow oven is not simply its technical specifications, but a design approach that starts by working backward from real-world production constraints.

– Installation space is limited

– The production capacity of a large reflow oven is unnecessary

– Repeatability cannot be compromised

– Faster evaluation and prototyping cycles are required

By continuously questioning what a “compact reflow oven” should be, the UNI series has arrived at a clear answer: not compromising because it is small, but optimizing precisely because it is small.

ANTOM will continue to redefine and evolve the value of compact reflow ovens.

Specifications of the Nitrogen-Compatible Compact Reflow Oven UNI Series

For detailed specifications (options) of the UNI Series small reflow ovens, please refer to the individual model pages (click on the model name below to move).

| Model name | Total length of device | Number of zones | Effective board width |

|---|---|---|---|

| UNI-6120 | 1,590mm (1,890) | Heating 6(1) | 50~200mm |

| UNI-6131 | 1,990mm | Heating 6 (1) | 50-310mm |

| UNI-6146 | 1,990mm | Heating 6 (1) | 50-460mm |

Click on the model name to go to the details page.

*The ( ) in the total length indicates the total length of the mesh type.

*The ( ) in the number of zones indicates the number of cooling zones.

Options available for applications where ambient air is sufficient

Not all heating processes require a nitrogen atmosphere.

At ANTOM, we also offer dedicated ovens optimized for operation in ambient air environments.

By eliminating unnecessary features, these systems reduce initial investment and operational burden while reliably meeting the performance required for assembly and thermal processing.

ANTOM proposes air-only ovens designed with exactly what is needed—no more, no less.

For detailed specifications (options) of the UNI Series compact atmospheric reflow ovens, please refer to the individual model pages (click on the model name below to move).

| Model name | Total length of device | Number of zones | Effective board width |

|---|---|---|---|

| UNI-5020 | 1,290mm (1,590) | Heating 5 | 50~200mm |

| UNI-5031 | 1,290mm (1,590) | Heating 5 | 50-310mm |

Click on the model name to go to the details page.

*The total length in parentheses is the total length of the mesh type.

If standard specifications are not sufficient, please consult with us

At ANTOM, we also provide custom-built and customized solutions based on our compact reflow ovens.

While the UNI series is designed to cover a wide range of applications, there are cases where standard specifications may not fully meet requirements due to workpiece geometry, thermal mass, or specific process conditions.

If you feel that “off-the-shelf equipment is almost enough, but not quite,” we encourage you to contact us for consultation.

→ Learn more about customization options for compact reflow ovens

For inquiries regarding the UNI compact reflow oven series, please use the form below.

For inquiries regarding the heating equipment (small reflow, drying oven) or peripheral equipment provided by our company, please use the form below.

Please feel free to contact us for consultations regarding the introduction of heating equipment, as well as demonstrations using actual equipment and profile measurements.