2025年2月8日

Medium-sized reflow oven (N2 compatible) SOL-6136N

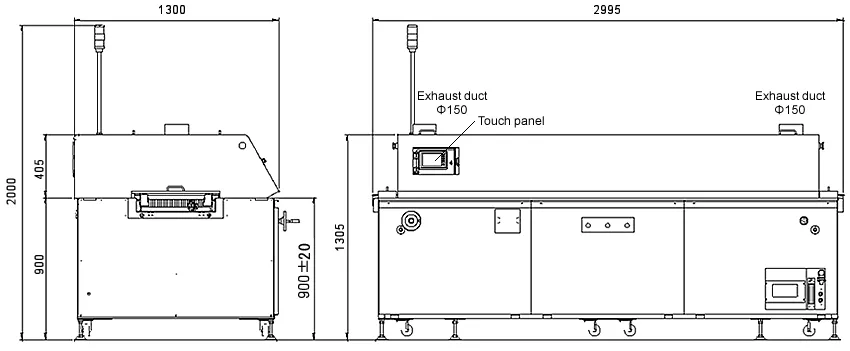

Exterior dimensions

Basic specifications

| Number of zones | 6 heating zones / 1 cooling zone |

|---|---|

| Heating method | Upper hot air + far infrared heating/lower far infrared heating method |

| Maximum set temperature | Top 320℃ / Bottom 350℃ |

| Effective board width | 50~360mm |

| Transport method (selectable) | Pin chain transport/mesh transport |

| Transport speed | 0.3~1.5m/min |

| Part effective height | Top surface 10mm / Bottom surface 10mm |

| Oxygen concentration meter | Standard equipped |

| Flux recovery | Equipped as standard (simple maintenance type) |

| Supported languages | Japanese/English/Chinese/Korean |

| PC outlet | 1 piece (100V) |

| Board mounting allowance | 4mm |

| Pass line | 900+20,-15mm |

| Input power supply | AC200V 3φ 56kVA 161A |

| Device dimensions | L2,995×D1,300×H1,305mm |

| Device weight | 1,300kg |

Options

| Automatic width adjustment mechanism |

| Through type warp prevention mechanism (elevating type) |

| Addition of lower circulation fan |

| Labyrinth vertical lifting mechanism |

| Overheating prevention device |

| Board drop sensor |

| Oxygen concentration controller |

| N2 all zone supply |

| Oxygen concentration all zone sampling |

| Low oxygen concentration specifications (100ppm or less) |

| Cooling reinforcement unit/cooling chiller |

| UPS (uninterruptible power supply) |

| Power transformer |

| Entrance/exit conveyor extension |

| Circulation fan stop detection |

| Hood interlock |

| Emergency stop button position change |

| Reflow checker (profile measurement unit) |

| Various types of cooling conveyors and transport conveyors |

| Paint color change |

- Conveyance width: 360mm

- equipment size: 2000~3000mm

- Intended use: Reflow

- Number of zones: 6 zones

- air or nitrogen: N2 compatible

- Preset temperature: 320℃